- Fasteners Inspection System

- LED Display

- Gauging And Profile Display System

- Online Gauging System

- Code Reader

- Industrial Code Reader

- Pharma Code Reader

- Track And Trace System

- Electronic Cam Controller

- Locker Control System

- Vision System

- Smart Camera

- 13A ProCAM Smart Camera

- 13B-3D Laser Profiler

- 13C Embedded Vision

- 13D VC Smart Camera

- MIPI Modules

- Firewire Camera

- Shut Down Box Smart Classroom

- SBS Smart Classroom

- Engineering Training Systems

- Univision Smart Finder

- illumination for Machine Vision

- Dark Field Illumination

- Cloud Illumination

- Front Light

- Ring Light

- Bar Light

- Coaxial Light

- Back Light

- Red Back Light

- White Back Light

Procam Label Vision System

Product Details:

- Model No Procam LVS-400

- Voltage 230 V AC

- Accuracy Up to 99.5%

- Measurement Range 0.1 mm 300 mm

- Capacity Up to 400 bottles per minute

- Power Source Electric

- Temperature Range 0C to 50C

- Click to View more

Procam Label Vision System Price And Quantity

Procam Label Vision System Product Specifications

- 0C to 50C

- 600 mm x 400 mm x 200 mm

- Vision Inspection System

- Camera, LED Illumination, Control Panel, Software

- 50-60 Hz

- Aluminium, Stainless Steel

- Automatic

- High-Speed Detection, Real-Time Rejection

- Label Inspection on Bottles and Containers

- 230 V AC

- Procam LVS-400

- Approx. 25 kg

- Up to 99.5%

- 0.1 mm 300 mm

- Up to 400 bottles per minute

- Touch Screen Display

- Electric

Product Description

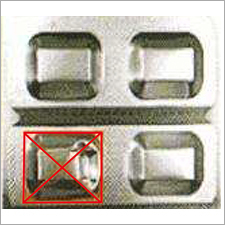

We are engrossed in supplying the top-of-the-line Procam Label Vision System that is popularly known among our customers owing to its superior design and performance. It is an advanced industrial device designed for the vision-based inspection of a blister. It is capable of detecting various defects such as broken products, color variation, shape and size variation, and foreign products contained in the blisters. Owing to its high operational efficiency and reliable performance, we are seeing a huge demand for the Procam Label Vision System in the marketplace.

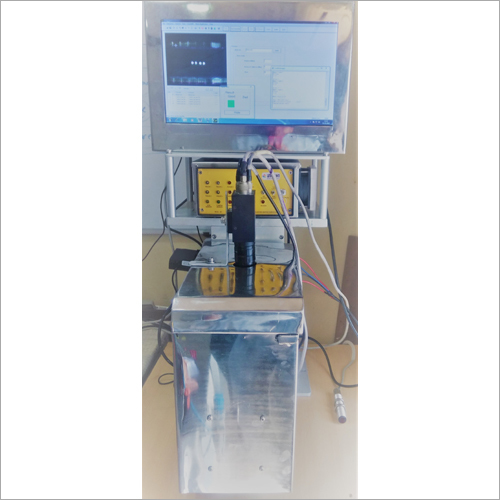

Equipped with smart camera, this system is used for quality checking of pharmaceutical packaging. Its state of the art image processing section includes bright LED based illumination arrangement, advanced optics with around 420 mm working distance covering capacity, state of the art Image Processing Library and a set of cables. Easy to comprehend HMI of this system reduces human effort, safe project duration and improves its productivity. This machine is capable of reading different sorts of codes that include data matrix code, bar code and pharma code.

Powerful High-Speed Detection

Procam LVS-400 delivers rapid, precise label inspection on production lines running up to 60 meters per minute. Its real-time rejection mechanism ensures defective products are automatically sorted out, maintaining quality control without slowing operations. Designed to support up to 400 bottles per minute, the system suits both exporters and manufacturers who require swift and accurate label verification in demanding environments.

Intuitive User Experience and Data Connectivity

The system features a multi-language touch screen interface, making operation simple for staff across diverse regions. Users can effortlessly export inspection data and images via USB and Ethernet connectivity, streamlining traceability and compliance. Statistical analysis, automatic product learning, and image storage further enhance monitoring and decision-making efficiency, supporting modern production management requirements.

Robust and Flexible Installation

Built with industrial-grade aluminium and stainless steel, the Procam LVS-400 offers reliability and adaptability for various facility layouts. Easy tool-free maintenance minimizes downtime, while options for conveyor mounting or standalone use allow seamless integration. The LED backlit illumination and reputation for low maintenance ensure consistent performance, even under fluctuating humidity and temperatures from 0C to 50C.

FAQ's of Procam Label Vision System:

Q: How does the Procam Label Vision System detect label misalignment and printing defects?

A: The LVS-400 employs high resolution CMOS cameras and LED backlighting to capture clear images of each bottle or container. Advanced software analyzes these images in real-time to identify misaligned, missing, or poorly printed labels with up to 99.5% accuracy.Q: What connectivity options are available for exporting inspection data and images?

A: Data export is supported via USB and Ethernet interfaces, enabling easy transfer of statistical reports, images, and system logs for further processing or compliance documentation.Q: When should the vision inspection system be used during production?

A: The Procam LVS-400 is typically installed in-line, either as conveyor-mounted or standalone, to inspect each item immediately after labeling. This early intervention helps prevent defective products from proceeding further down the production chain.Q: Where can the Procam LVS-400 be installed within a facility?

A: Thanks to its compact design (600 mm x 400 mm x 200 mm) and flexible mounting options, the system can be placed directly on labeling conveyors or as a dedicated standalone inspection station, fitting most bottle or container packaging lines.Q: What is the process for handling products that fail inspection?

A: Products failing inspection-due to misalignment, missing labels, or unreadable codes-are automatically sorted out through the real-time rejection mechanism. The system also provides audio-visual alarms to notify operators of detected issues.Q: How does automatic product learning enhance system efficiency?

A: Automatic product learning enables the LVS-400 to adapt quickly to new label designs or formats, minimizing setup time and reducing the need for manual adjustments between changeovers.Q: What are the main benefits of using Procam LVS-400 for label inspection?

A: Key advantages include high-speed accurate detection, low maintenance with tool-free access, intuitive multi-language operation, reliable compliance with CE standards, and seamless data management for exporters, manufacturers, and suppliers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese