- Fasteners Inspection System

- LED Display

- Gauging And Profile Display System

- Online Gauging System

- Code Reader

- Industrial Code Reader

- Pharma Code Reader

- Track And Trace System

- Electronic Cam Controller

- Locker Control System

- Vision System

- Smart Camera

- 13A ProCAM Smart Camera

- 13B-3D Laser Profiler

- 13C Embedded Vision

- 13D VC Smart Camera

- MIPI Modules

- Firewire Camera

- Shut Down Box Smart Classroom

- SBS Smart Classroom

- Engineering Training Systems

- Univision Smart Finder

- illumination for Machine Vision

- Dark Field Illumination

- Cloud Illumination

- Front Light

- Ring Light

- Bar Light

- Coaxial Light

- Back Light

- Red Back Light

- White Back Light

ProCam BVS Blister Vision System

Product Details:

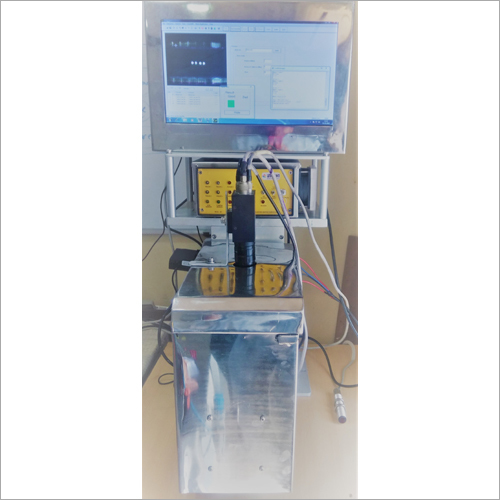

- Core Components Camera, Lens, LED Illumination Bar, Controller, HMI

- Model No ProCam BVS

- Voltage 230 V AC

- Automation Grade Automatic

- Measurement Range Up to A4 blister size

- Feature 100% automatic defect detection, false rejection minimization, high speed operation

- Power Source Electric

- Click to View more

ProCam BVS Blister Vision System Price And Quantity

ProCam BVS Blister Vision System Product Specifications

- Up to A4 blister size

- Approx. 55 kg

- Automatic

- 230 V AC

- ProCam BVS

- Automated blister pack inspection

- Camera, Lens, LED Illumination Bar, Controller, HMI

- 50/60 Hz

- Electric

- 100% automatic defect detection, false rejection minimization, high speed operation

- 900 x 560 x 1610 mm

- Stainless Steel (SS304/SS316), Industrial Aluminum

- Up to 99.9%

- Touch Screen HMI

- 10C to 45C

- Blister Vision Inspection System

- Up to 300 blisters/min

Product Description

ProCam BVS Blister Vision System is an advanced industrial device that is widely demanded in the marketplace owing to its unmatched ergonomics and user-friendly features. This device is designed and assembled in our ultra-advanced production site with the help of cutting-edge techniques and machinery. ProCam BVS Blister Vision System is easy to install and operate. It is an efficient and reliable industrial device. Our esteemed clients can get the device delivered to their doorstep within the stipulated time frame.

More information

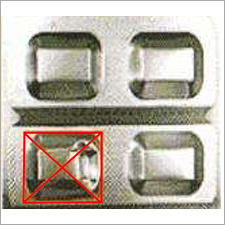

This system acts as economical option to verify quality of blister. Known for its user friendly mechanism, this system comprises of ConfiCam VC and ProCam software programs to simplify image processing function. This high speed system is easy to manage for higher productivity. Special design of its smart camera eliminates the necessity of using separate controller for its advanced features.

Special features of this machine

This system is perfect for checking various features of capsules and tablets (equipped with aluminum foil/transparent or amber PVC foil). It can check maximum six blister lines without any interruption. It also has data back up facility that conforms to global standard and arrangement for sending password administration report.

Advanced Vision Inspection Technology

ProCam BVS is built with a high-resolution 5 MP camera and a custom-designed shadow-less LED lighting system. Together, they deliver unmatched image clarity and precision, ensuring every blister is inspected at high speed and with maximum accuracy. This setup effectively minimizes false rejections and enhances overall product quality assurance for manufacturers.

Effortless Compliance and Data Management

The system is compliant with 21 CFR Part 11 and CE requirements, supporting regulated industries. Batch-wise inspection records and exportable reports simplify both documentation and audit processes. Its user-friendly, multilingual touchscreen HMI interface further streamlines operations, allowing clear access to data and system controls regardless of operator expertise.

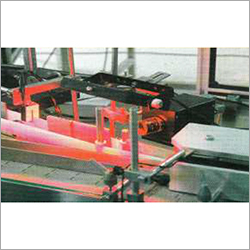

Rapid, Reliable, and Seamless Integration

Engineered for seamless mounting onto blister packing machines, ProCam BVS delivers rapid response times of less than 50ms per inspection and can handle up to 300 blisters per minute. The compact, robust design in durable stainless steel and aluminum ensures consistent performance in demanding pharmaceutical production environments.

FAQs of ProCam BVS Blister Vision System:

Q: How does the ProCam BVS Blister Vision System detect defects in blister packs?

A: The ProCam BVS uses a 5 MP industrial vision camera combined with custom shadow-less LED lighting to capture high-quality images of each blister. Advanced processing algorithms automatically inspect for defects with up to 99.9% accuracy, ensuring only conforming products pass through.Q: What is the process for integrating ProCam BVS into an existing blister packing line?

A: The system is designed for direct mounting on blister packing machines. It connects easily via Ethernet, USB, or RS232 interfaces, requiring minimal setup. Integration is straightforward and supported by the user-friendly touchscreen HMI and comprehensive installation guidance from the manufacturer.Q: When should I use the automatic reject unit?

A: The automatic pneumatic reject mechanism is always engaged during normal operation. When a defect is detected, the system instantly activates the reject unit to remove faulty blisters from the line, ensuring only quality products proceed to packaging.Q: Where are the inspection results and data stored?

A: Inspection records are stored batch-wise within the system and can be exported as reports for compliance or analysis. This feature makes audits, traceability, and documentation highly efficient for regulatory environments.Q: What are the main benefits of using ProCam BVS for blister pack inspection?

A: Key benefits include reliable 100% automatic defect detection, minimal false rejection rates, compliance with international standards, high-speed operation (up to 300 blisters/min), and easy-to-use multilingual controls. The system helps manufacturers maintain product quality and satisfy strict regulatory requirements.Q: How does ProCam BVS ensure regulatory compliance in pharmaceutical production?

A: It is fully compliant with 21 CFR Part 11 and CE standards, supporting secure, audit-ready data management and robust inspection processes required in regulated environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese