- Fasteners Inspection System

- LED Display

- Gauging And Profile Display System

- Online Gauging System

- Code Reader

- Industrial Code Reader

- Pharma Code Reader

- Track And Trace System

- Electronic Cam Controller

- Locker Control System

- Vision System

- Smart Camera

- 13A ProCAM Smart Camera

- 13B-3D Laser Profiler

- 13C Embedded Vision

- 13D VC Smart Camera

- MIPI Modules

- Firewire Camera

- Shut Down Box Smart Classroom

- SBS Smart Classroom

- Engineering Training Systems

- Univision Smart Finder

- illumination for Machine Vision

- Dark Field Illumination

- Cloud Illumination

- Front Light

- Ring Light

- Bar Light

- Coaxial Light

- Back Light

- Red Back Light

- White Back Light

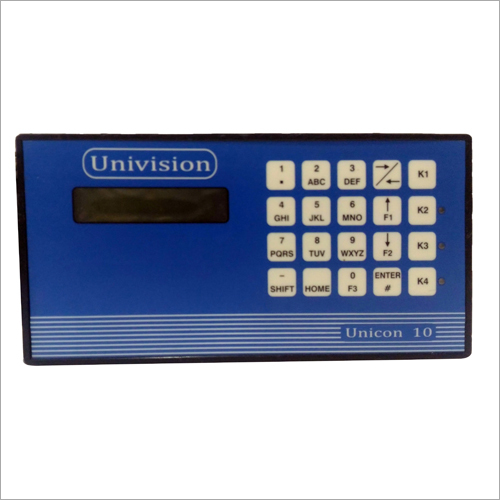

Electronic CAM With Controller

Product Details:

- Capacity Customizable / As per requirement

- Core Components Electronic CAM, Controller Unit, Display Module

- Frequency 50/60 Hz

- Accuracy 0.02 mm

- Power Source Electric

- Temperature Range 0C to 50C (Operating)

- Automation Grade Automatic

- Click to View more

Electronic CAM With Controller Price And Quantity

Electronic CAM With Controller Product Specifications

- Industrial Automation and Synchronization

- Digital Display

- EC-CAM100

- High Accuracy Synchronization, Programmable CAM Profiles, User-Friendly Interface

- 220V AC

- 0360 (CAM Angle)

- Automatic

- Electronic CAM, Controller Unit, Display Module

- Electronic CAM with Controller

- Customizable / As per requirement

- 320 x 240 x 120 mm (approx.)

- Industrial Grade Metal Housing

- 50/60 Hz

- Approx. 5-10 kg

- 0C to 50C (Operating)

- 0.02 mm

- Electric

Product Description

Backed by a team of adroit professionals, we are engrossed in supplying the top-of-the-line Electronic CAM With Controller that is widely acclaimed among our customers owing to its superior design and unmatched quality. It is a freely selectable and configurable cam. Owing to its high precision and unmatched ergonomics, it is preferred by our customers. It is interfaced via RS232. Electronic CAM With Controller is easy to install and operate. It does not degrade in quality or performance for years.

More details

This system uses Master Controller technology for its uninterrupted operation. This single phase system requires around 1A current to operate. It can be used at maximum 40 degree C operating temperature. Vertex positioning facility of this electronic system enables it to detect and compensate vertex positioning error. Its six channel based programmable cam maintains its high precision level. Its production counter has 6 digits based display arrangement. This user friendly system uses Rs-485 operating interface which is easy to handle. This electronic cam can maintain maximum 359 degree angle display for optimum performance while capturing images.

Advanced Synchronization and Precision

Achieve unparalleled synchronization accuracy with the EC-CAM100 Electronic CAM With Controller. Its 0.02 mm precision and rapid response time of less than 1 ms make it ideal for demanding automation tasks. The system allows for programmable CAM profiles, ensuring custom operation to meet varied process requirements.

Flexible Integration and Connectivity

The EC-CAM100 is designed for seamless integration with industrial systems. It supports both digital and analog input signals, multiple communication protocols-including RS232, RS485, and optional Ethernet-and is easily expandable. Panel or wall mounting options add flexibility to installation across factories and plants.

Robust Build and Compliance

Built with an industrial-grade metal housing and certified to CE standards, the EC-CAM100 provides reliable protection (IP54/IP65) against dust and water ingress. Operating within a broad temperature and humidity range, it is engineered for durability and long-term, trouble-free operation in industrial environments.

FAQ's of Electronic CAM With Controller:

Q: How does the Electronic CAM With Controller enhance industrial automation?

A: The EC-CAM100 delivers high-precision synchronization and automated control, supporting programmable CAM profiles. Its rapid response time (<1 ms) ensures accurate execution of commands, making it highly effective for processes requiring precise timing and position control in industrial automation.Q: What programming methods are available for this controller?

A: You can program the EC-CAM100 Electronic CAM using either its built-in keypad or a modern touch interface. Both methods are user-friendly, facilitating efficient parameter setup, profile management, and on-site adjustments.Q: When is the unit's memory useful and how secure is data storage?

A: The non-volatile memory in the controller is critical when you need to store and recall multiple CAM profiles across power cycles or shifts. Your data remains safeguarded even if the unit is powered down, ensuring operational continuity and profile integrity.Q: Where can this controller be installed and what mounting options are available?

A: Designed for industrial flexibility, the EC-CAM100 supports both panel and wall mounting. Its sturdy enclosure and IP54/IP65 protection make it suitable for operation in a wide range of industrial environments, from factory floors to control rooms.Q: What are the main benefits of its connectivity options?

A: With RS232, RS485, and optional Ethernet support, the EC-CAM100 offers seamless integration with existing automation systems. These interfaces allow easy communication between machines, PLCs, and supervisory control, streamlining process coordination and data exchange.Q: How does the device aid in process synchronization and accuracy?

A: It employs advanced electronics to deliver synchronization with up to 0.02 mm accuracy and less than 1 ms response time. This precision is essential in applications where coordinated movements or outputs are required, reducing errors and enhancing process reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese