- Fasteners Inspection System

- LED Display

- Gauging And Profile Display System

- Online Gauging System

- Code Reader

- Industrial Code Reader

- Pharma Code Reader

- Track And Trace System

- Electronic Cam Controller

- Locker Control System

- Vision System

- Smart Camera

- 13A ProCAM Smart Camera

- 13B-3D Laser Profiler

- 13C Embedded Vision

- 13D VC Smart Camera

- MIPI Modules

- Firewire Camera

- Shut Down Box Smart Classroom

- SBS Smart Classroom

- Engineering Training Systems

- Univision Smart Finder

- illumination for Machine Vision

- Dark Field Illumination

- Cloud Illumination

- Front Light

- Ring Light

- Bar Light

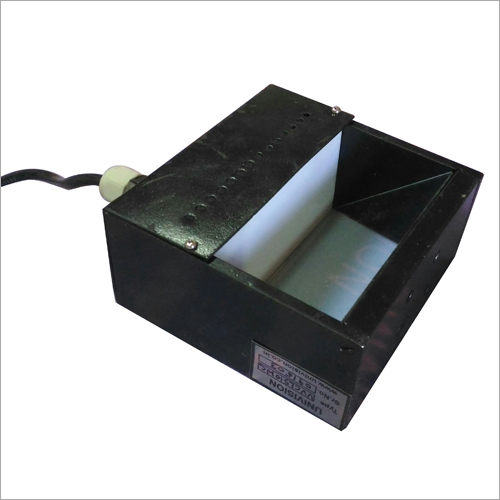

- Coaxial Light

- Back Light

- Red Back Light

- White Back Light

Machine Vision Co-Axial Light

Product Details:

- Core Components High-Intensity LED Array, Diffusion Plate, Optical Lens, Heat Sink

- Frequency 50/60 Hz

- Automation Grade Automatic

- Accuracy High Lighting Uniformity (>90%)

- Model No MV-COAX-100

- Measurement Range Supports Up To 150mm Field of View

- Voltage 24V DC

- Click to View more

Machine Vision Co-Axial Light Price And Quantity

- 34000 INR/Piece

- 1 Piece

Machine Vision Co-Axial Light Product Specifications

- 100mm x 40mm x 30mm

- 50/60 Hz

- Automatic

- High Lighting Uniformity (>90%)

- High-Intensity LED Array, Diffusion Plate, Optical Lens, Heat Sink

- Anodized Aluminum Alloy Housing

- Co-Axial Light (Machine Vision)

- Machine Vision Inspection Illumination

- DC Power Supply

- Uniform Illumination, Flicker-Free, High Brightness, Long Lifespan

- 24V DC

- MV-COAX-100

- Supports Up To 150mm Field of View

- -20C to 60C

- Approx. 200g

Machine Vision Co-Axial Light Trade Information

- 10000 Piece Per Day

- 1 Week

Product Description

Machine Vision Co-Axial Light is an industry-specific light that is used to provide a type of diffuse illumination, generated from an internal source. It helps allow light from the object to be collected by the camera above. Owing to its high build quality, sturdy construction, and resilience, it is preferred by our customers. Coaxial Light has got high operational efficiency, unmatched strength, and longevity, therefore, we are seeing a huge demand for Machine Vision Co-Axial Light in the marketplace.

Specification

Brand | Univision |

Usage/Application | Machine Vision Systems |

Controller | External strobe command |

Voltage | 24 V DC |

Country of Origin | Made in India |

Industry | Pharma, Food, Printing, Packaging, Automobile, Semiconductor & more |

Source | LED |

Standard | cGMP, US FDA 21 CFR Part 11 compliant |

Unmatched Illumination Uniformity

The MV-COAX-100 delivers high uniformity (>90%), which is critical for machine vision applications that require consistent lighting across the target area. Its advanced optical design ensures minimal shadowing and superior detection of surface defects, edges, or markings, supporting high-accuracy automated inspection and measurement processes.

Robust and Versatile Design

Engineered with anodized aluminum alloy housing and IP54 ingress protection, this light is well-suited to demanding manufacturing environments. It operates reliably across a broad temperature range (-20C to 60C) and resists humidity from 10% to 85% RH. The M4 threaded mounting holes and 1.5-meter cable enable flexible, secure installation in varied setups.

Flexible Control and Color Options

Adapt the lighting setup to your inspection needs with a built-in brightness controller and an optional external control. Available color temperatures include white (6500K), red, blue, and infrared, offering optimal contrast for a broad spectrum of materials and surfaces. The instant ON/OFF switching (<1ms) enhances synchronization with high-speed vision systems.

FAQ's of Machine Vision Co-Axial Light:

Q: How does the Machine Vision Co-Axial Light improve inspection accuracy?

A: The light's high-intensity LED array and diffusion plate generate exceptionally uniform and flicker-free illumination, minimizing shadows and reflections. This uniformity ensures even exposure of the inspection area, enabling machine vision systems to detect minute defects or features with high precision.Q: What is the typical working distance and supported field of view?

A: The MV-COAX-100 has a typical working distance of 30mm to 120mm and supports a field of view up to 150mm, making it ideal for medium-scale inspection tasks where accurate, even lighting across the subject is needed.Q: Where can this co-axial light be mounted, and how is it installed?

A: The light features M4 threaded mounting holes on its durable housing, allowing for secure attachment to inspection machines, conveyors, or custom fixtures. Its 1.5-meter cable (customizable on request) facilitates flexible placement even in space-constrained setups.Q: What are the available color options and their benefits?

A: The standard color temperature is 6500K (white), suitable for general inspection. Red, blue, and IR versions are available upon request, each enhancing contrast or revealing specific features for different materials or surfaces during machine vision inspections.Q: How is brightness controlled and can it be automated?

A: Brightness adjustment is managed via an integrated controller, with an option for external control to facilitate integration with automated vision systems. This flexibility ensures optimal image capture quality in varying environmental and substrate conditions.Q: When is maintenance required, and how durable is the light?

A: Thanks to its passive air cooling and robust, anodized aluminum housing, the MV-COAX-100 requires minimal maintenance. The LED lifespan exceeds 50,000 hours, reducing replacement needs and downtime in continuous-use environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese