- Fasteners Inspection System

- LED Display

- Gauging And Profile Display System

- Online Gauging System

- Code Reader

- Industrial Code Reader

- Pharma Code Reader

- Track And Trace System

- Electronic Cam Controller

- Locker Control System

- Vision System

- Smart Camera

- 13A ProCAM Smart Camera

- 13B-3D Laser Profiler

- 13C Embedded Vision

- 13D VC Smart Camera

- MIPI Modules

- Firewire Camera

- Shut Down Box Smart Classroom

- SBS Smart Classroom

- Engineering Training Systems

- Univision Smart Finder

- illumination for Machine Vision

- Dark Field Illumination

- Cloud Illumination

- Front Light

- Ring Light

- Bar Light

- Coaxial Light

- Back Light

- Red Back Light

- White Back Light

Industrial Blister Vision System

Product Details:

- Capacity Up to 300 blisters per minute

- Temperature Range 0C to 50C

- Accuracy 99% detection accuracy

- Automation Grade Fully Automatic

- Measurement Range Customizable as per blister size

- Feature Real-time Defect Detection, Auto Ejection, Reporting

- Model No IBVS-300

- Click to View more

Industrial Blister Vision System Product Specifications

- 220V AC

- IBVS-300

- Real-time Defect Detection, Auto Ejection, Reporting

- 50/60 Hz

- AC Electric

- HD Industrial Camera, LED Backlight, Control PC

- Fully Automatic

- Industrial Touchscreen Display

- Customizable as per blister size

- Industrial Vision Inspection System

- 0C to 50C

- 99% detection accuracy

- Approx. 45 kg

- Stainless Steel with Aluminum Housing

- Up to 300 blisters per minute

- 650 mm x 450 mm x 1600 mm

- Blister Packaging Line Quality Control

Product Description

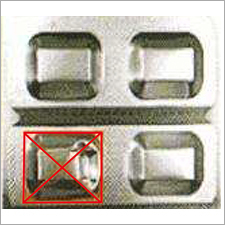

Industrial Blister Vision System is an advanced industrial device that is used for monitoring and inspection applications. It is capable of detecting various defects including broken products, color variation, shape and size variation, and foreign products contained in the blisters. Owing to its high build quality and reliable performance, this system is preferred by our customers. It is a vision-based inspection device. Our customers can get the Industrial Blister Vision System at a reasonable price.

This online inspection system is extensively used in pharmaceutical industry as important part of quality testing job. This machine is capable of identifying missing drug ( tablet/capsule), damaged tablet ( caused by cracking/broken form), presence of foreign matter in drugs, size variation of medicine ( under size and over size), color variation and also missing cap of capsules. This system uses advanced BIS software with password protection arrangement. This software is capable of showing live as well as threshold images of products. Parameters of this machine are adjustable for its better performance.

Specification

Brand | Univision |

Voltage | 230 V AC + /- 10 % at 50 HZ + /- 3 Hz |

Country of Origin | Made in India |

Industry | Pharma, Food, Engineering packaging |

Speed | From 60 Blisters to more than 800 Blisters per minute |

Tracks | Multiple |

Pickers | Max 4 per track |

Inputs | Mechanical CAM or Encoder based electronic CAM |

Substrate | Alu- Alu / PVC Amber , PVC clear |

Standard | cGMP, US FDA 21 CFR Part 11 compliant |

Operate Interface | User friendly GUI |

Password Protection | Yes |

Reports | MIS Reports |

Rejection | Automatic signal to Pickers |

Advanced Blister Inspection Technology

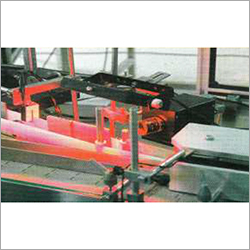

Equipped with a high-resolution 12 MP industrial camera and high-intensity LED backlight, the IBVS-300 delivers exceptional defect detection for blister packaging. Its system can handle multiple configurable inspection zones, adapting to various product sizes and needs. With rapid processing times and automatic ejection of faulty products, the system ensures that only quality items proceed down the line, reducing rework and waste.

Seamless Integration and Operation

Operating on an industrial Windows or Linux platform, the unit connects via Ethernet, USB, and Digital I/O for easy integration with existing production systems. The spacious 21.5-inch color touch panel provides an intuitive interface for operators, and the robust 1TB data storage supports extensive batch reporting. Its IP54-rated enclosure and adjustable mounts offer secure installation in diverse production environments.

Compliance, Reliability, and Efficiency

Manufactured from stainless steel and aluminum, the IBVS-300 is designed for resilience in tough industrial environments, handling humidity up to 90% and temperatures from 0C to 50C. Fully CE and GMP compliant, the system also prioritizes safety with features like emergency stop and overload protection. Remote diagnostics and on-site service options provide ongoing support and reliability for continuous operation.

FAQ's of Industrial Blister Vision System:

Q: How does the IBVS-300 Industrial Blister Vision System ensure a high level of defect detection accuracy?

A: The IBVS-300 utilizes a 12 MP HD industrial camera and advanced image processing software, achieving 99% detection accuracy. High-intensity LED backlighting enhances visibility, while customizable inspection zones and real-time defect detection ensure precise quality control for each blister pack.Q: What are the main benefits of using this system on a blister packaging line?

A: The primary benefits include increased production efficiency, automatic rejection of defective packs, reliable batch reporting, and significant reduction of manual inspection errors. Its robust design, compliance with GMP and CE standards, and easy-to-use interface all contribute to consistent, top-tier product quality.Q: When and where should the IBVS-300 be implemented in a manufacturing facility?

A: The IBVS-300 is best installed directly on the blister packaging line as products move along the conveyor. Its adjustable floor stand and compact dimensions make it suitable for various industrial environments, especially in pharmaceutical, food, and consumer goods facilities requiring rigorous quality monitoring.Q: What is the process for integrating this vision system into an existing line?

A: Integration is straightforward, thanks to its versatile connectivity options (Ethernet, USB, Digital I/O) and user-friendly HMI. Once mounted and connected, inspection zones can be configured according to blister size, and operators can immediately start batch reporting and reject tracking using the included software.Q: How can users access and utilize the inspection data stored by the system?

A: Inspection data and batch reports are saved to the integrated 1TB HDD/SSD. Users can export reports or statistics via Ethernet or USB for auditing, analysis, or compliance documentation. The touchscreen HMI enables easy on-site navigation and retrieval of specific production records.Q: What support and safety features are included with the IBVS-300?

A: The system features emergency stop and overload protection for operator safety. Maintenance support includes both remote diagnostics and on-site service, ensuring minimal downtime and prompt troubleshooting. The rugged IP54 enclosure safeguards components in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese