- Fasteners Inspection System

- LED Display

- Gauging And Profile Display System

- Online Gauging System

- Code Reader

- Industrial Code Reader

- Pharma Code Reader

- Track And Trace System

- Electronic Cam Controller

- Locker Control System

- Vision System

- Smart Camera

- 13A ProCAM Smart Camera

- 13B-3D Laser Profiler

- 13C Embedded Vision

- 13D VC Smart Camera

- MIPI Modules

- Firewire Camera

- Shut Down Box Smart Classroom

- SBS Smart Classroom

- Engineering Training Systems

- Univision Smart Finder

- illumination for Machine Vision

- Dark Field Illumination

- Cloud Illumination

- Front Light

- Ring Light

- Bar Light

- Coaxial Light

- Back Light

- Red Back Light

- White Back Light

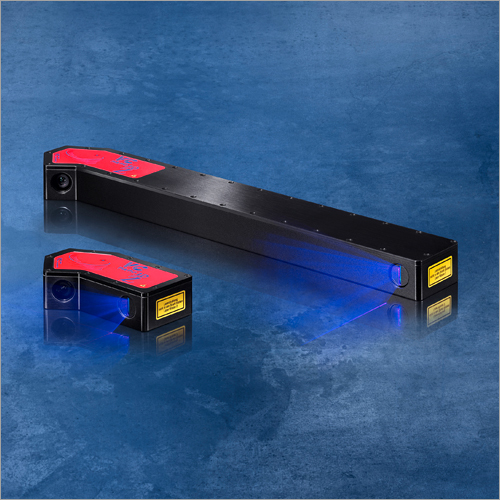

VCnano3DZ Laser Profiler

Product Details:

- IR Distance Working distance: 55 mm to 450 mm, depending on model

- Aperture Fixed (integrated)

- Sensor Size 3D CMOS sensor

- Sensor High-speed CMOS, blue laser

- Media Type Ethernet Data Output

- Technology Laser triangulation

- Features IP67 rated, compact body, high accuracy, multiple mounting options

- Click to View more

X

VCnano3DZ Laser Profiler Product Specifications

- 3D Laser Profiler

- Standard field of view: 20-180 mm (varies by model)

- Up to 2048 points/profile

- Integrated industrial lens

- High-precision 3D measurement, Real-time profile acquisition

- IP67 rated, compact body, high accuracy, multiple mounting options

- No display (industrial sensor)

- Real-time 3D data streaming

- 1920 x 1200 pixels

- Laser triangulation

- Digital region of interest selection

- Not applicable (wired device)

- Industrial Grey/Black

- High-speed CMOS, blue laser

- 3D CMOS sensor

- Ethernet Data Output

- Fixed (integrated)

- Aluminum alloy, industrial grade

- Working distance: 55 mm to 450 mm, depending on model

Product Description

We are engrossed in supplying the top-of-the-line VCnano3DZ Laser Profiler that is a type of laser displacement sensor. It can collect height data across a laser line. The device enables 2D and 3D measurements such as height difference, width, or angle using a sensor. Owing to its unmatched ergonomics, user-friendly design, and performance, we are seeing a huge demand for the VCnano3DZ Laser Profiler in the marketplace. It does not degrade in quality or become inferior in the long run. Our customers can approach us to purchase the device at a reasonable price.

Exceptional 3D Measurement Accuracy

The VCnano3DZ Laser Profiler achieves outstanding measurement accuracy, reaching up to 2 micrometers. Utilizing a sophisticated blue laser and high-speed CMOS sensor, the device captures fine surface details in challenging industrial settings, aiding efficient quality inspections and complex 3D profiling tasks.

Robust and Versatile for Industrial Environments

Designed with IP67-rated, industrial-grade aluminum alloy housing, the VCnano3DZ withstands dust, water, and mechanical impacts. Its compact size and multiple mounting options accommodate various spaces and setups, making it a versatile solution for manufacturers and automation specialists.

Flexible Integration and Real-Time Data Output

Equipped with Gigabit Ethernet and RS-232 output interfaces, the VCnano3DZ ensures seamless integration with existing automation systems. Real-time profile acquisition and 3D data streaming facilitate immediate quality feedback and process optimization for increased manufacturing efficiency.

FAQ's of VCnano3DZ Laser Profiler:

Q: How does the VCnano3DZ Laser Profiler achieve such high measurement accuracy?

A: The profiler employs laser triangulation with a high-speed CMOS sensor and integrated industrial lens, enabling highly precise 3D surface measurements accurate to 2 micrometers even on fast-moving objects.Q: What are the main benefits of using the VCnano3DZ in industrial automation?

A: It offers rapid, high-resolution 3D profile acquisition, robust IP67 protection, and flexible integration for real-time inspection and automated quality control, ultimately improving production efficiency and reducing defects.Q: When is it ideal to use the VCnano3DZ Laser Profiler?

A: This device is ideal for applications requiring meticulous quality inspection, inline process monitoring, precise object profiling, and automated sorting in challenging industrial environments.Q: Where can the VCnano3DZ be installed within an automation system?

A: Thanks to its compact design and multiple mounting options, the profiler can be installed in tight spaces on production lines, robotic arms, or conveyor systems wherever accurate 3D measurements are required.Q: What output interfaces are available for system integration?

A: The VCnano3DZ offers Gigabit Ethernet and RS-232 communication ports for easy integration into various industrial control and data acquisition systems.Q: How does real-time 3D data streaming enhance production processes?

A: Real-time data streaming provides instant feedback on product quality or process deviations, enabling immediate adjustments and minimization of production errors or waste.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese