- Fasteners Inspection System

- LED Display

- Gauging And Profile Display System

- Online Gauging System

- Code Reader

- Industrial Code Reader

- Pharma Code Reader

- Track And Trace System

- Electronic Cam Controller

- Locker Control System

- Vision System

- Smart Camera

- 13A ProCAM Smart Camera

- 13B-3D Laser Profiler

- 13C Embedded Vision

- 13D VC Smart Camera

- MIPI Modules

- Firewire Camera

- Shut Down Box Smart Classroom

- SBS Smart Classroom

- Engineering Training Systems

- Univision Smart Finder

- illumination for Machine Vision

- Dark Field Illumination

- Cloud Illumination

- Front Light

- Ring Light

- Bar Light

- Coaxial Light

- Back Light

- Red Back Light

- White Back Light

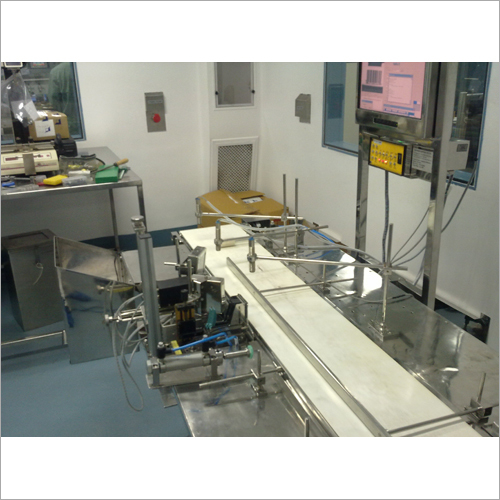

Industrial Track and Trace System

Product Details:

- Voltage 230V AC

- Core Components Industrial PC, RFID Reader, Barcode Scanner, PLC, Sensors

- Capacity Up to 100,000 units per day

- Model No ITT-800

- Power Source Electric

- Temperature Range -10C to 60C

- Accuracy 0.5%

- Click to View more

Industrial Track and Trace System Price And Quantity

Industrial Track and Trace System Product Specifications

- Real-time Monitoring, Data Logging, Remote Access, Error Detection

- Fully Automatic

- High grade stainless steel and industrial grade plastic

- 1600mm x 900mm x 1700mm

- Industrial Product Monitoring and Authentication

- Touch Screen HMI

- Variable, product dependent

- 50/60 Hz

- 0.5%

- Approx. 120 kg

- Electric

- ITT-800

- -10C to 60C

- 230V AC

- Up to 100,000 units per day

- Automatic Industrial Track and Trace System

- Industrial PC, RFID Reader, Barcode Scanner, PLC, Sensors

Product Description

Backed by a team of adroit professionals, we are engrossed in supplying the best in line Industrial Track and Trace System that is popularly known among our customers owing to its superior design and unmatched quality. It is well designed and developed in our state-of-the-art production division with the help of pioneering in-house tools and techniques. Owing to its reliable performance, longevity, and resilience, we are seeing a huge demand for the Industrial Track and Trace System in the marketplace. Our customers can approach us to purchase the device at a reasonable price.

Specification

Brand | Univision |

Speed | From 60 objects to more than 900 objects per minute |

Substrate Volume | With Suitable Contrast |

Country of Origin | Made in India |

System | Automatic Batch coding system for on-line 100% inspection based on Smart Optical contact less Re |

Industry | Pharma , Food, Engineering packaging |

Application | OCR/OCV and decoding 1D Bar codes , 2 D Data Matrix bar codes and Pharma Code |

Tracks | Single |

Inputs | From sensor or Mechanical CAM or Encoder based electronic CAM |

Rejection | Automatic signal to rejection system |

Standard | CGMP, US FDA 21 CFR Part 11 compliant |

Supply Voltage | 230 V AC + /- 10 % at 50 HZ + /- 3 Hz |

Operator Interface | User friendly GUI |

Pass word Protection | Yes |

Reports | MIS Reports |

Efficient and Accurate Product Tracking

The ITT-800 brings advanced automation to industrial track and trace operations, ensuring accurate data capture and verification for a wide range of products. Its barcode and RFID technologies enable seamless identification, while the touch screen HMI facilitates intuitive operation and real-time status updates.

Robust Construction and Environmental Protection

Built for demanding industrial settings, the system features high-grade stainless steel and industrial-grade plastic, complemented by an IP54-rated enclosure. The equipment stands up to high humidity (up to 95% non-condensing) and temperatures ranging from -10C to 60C, ensuring dependable performance regardless of the environment.

Modular Design and Easy Maintenance

Serviceability is simplified through a modular design, allowing swift replacement or upgrade of core components. With low maintenance requirements, the ITT-800 minimizes downtime and reduces operating costs, safeguarding production efficiency.

FAQ's of Industrial Track and Trace System:

Q: How does the ITT-800 Track and Trace System benefit industrial operations?

A: The ITT-800 enhances operational efficiency by offering real-time monitoring, accurate product authentication, and robust error detection. Its automatic data logging and centralized control reduce manual efforts, ensuring compliance, traceability, and streamlined auditing for manufacturers and exporters.Q: What software compatibility does the ITT-800 offer?

A: The system supports both Windows and Linux platforms, providing seamless integration with existing factory management and ERP software. Data can be exported in CSV, XML, or customized formats for further analysis or reporting.Q: When is floor standing installation suitable for this system?

A: Floor standing installation of the ITT-800 is ideal in factory production lines or industrial environments where mobility is less critical and a stable, prominent setup is required. Its size (1600mm x 900mm x 1700mm) fits standard production areas, and strong build accommodates high-volume operations.Q: Where can the ITT-800 be used regarding environmental conditions?

A: The system's IP54-rated enclosure and robust materials make it suitable for various industrial environments, including those with temperature ranges from -10C to 60C and up to 95% non-condensing humidity. Its design withstands dust, moisture, and typical factory conditions.Q: How is user access managed on this system?

A: The ITT-800 employs multi-level user authentication, allowing configurable access rights for operators, supervisors, and administrators. This ensures sensitive data and system functions are securely managed, reducing risks of unauthorized access.Q: What is the process for data export and remote access?

A: Data export is straightforward using the touch screen HMI, enabling users to transfer logs and reports in CSV, XML, or custom file formats. Remote access is supported via WiFi or LAN for efficient monitoring and troubleshooting from offsite locations.Q: What maintenance is required for the ITT-800 system?

A: The system requires minimal maintenance due to its modular design and high-quality components. Routine checks on sensors, lighting, and core electronics are recommended, while easy-to-replace modules keep downtimes to a minimum.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese