- Fasteners Inspection System

- LED Display

- Gauging And Profile Display System

- Online Gauging System

- Code Reader

- Industrial Code Reader

- Pharma Code Reader

- Track And Trace System

- Electronic Cam Controller

- Locker Control System

- Vision System

- Smart Camera

- 13A ProCAM Smart Camera

- 13B-3D Laser Profiler

- 13C Embedded Vision

- 13D VC Smart Camera

- MIPI Modules

- Firewire Camera

- Shut Down Box Smart Classroom

- SBS Smart Classroom

- Engineering Training Systems

- Univision Smart Finder

- illumination for Machine Vision

- Dark Field Illumination

- Cloud Illumination

- Front Light

- Ring Light

- Bar Light

- Coaxial Light

- Back Light

- Red Back Light

- White Back Light

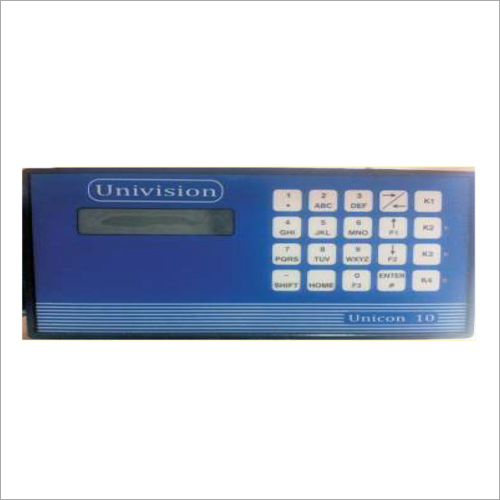

UNIPCR-10 Pharma Code Reader

Product Details:

- Voltage 230 V AC

- Temperature Range 10C to 40C

- Capacity 10 reads/min

- Core Components Optical Sensor, Controller, Display

- Model No UNIPCR-10

- Power Source AC Powered

- Measurement Range Reads all standard pharma bar codes

- Click to View more

X

UNIPCR-10 Pharma Code Reader Product Specifications

- High Accuracy, Portable, Compact Design

- Semi-Automatic

- 99.9%

- 50 Hz

- Mild Steel (MS) Powder Coated

- AC Powered

- Reads all standard pharma bar codes

- 6 kg

- UNIPCR-10

- LCD Digital Display

- 200 x 180 x 90 mm

- 10C to 40C

- 230 V AC

- Optical Sensor, Controller, Display

- Pharma Code Reader

- For reading and verifying pharma codes on packaging lines

- 10 reads/min

Product Description

UNIPCR-10 Pharma Code Reader is popularly known among our customers owing to its ergonomic design and bespoke specifications. It is easy to install and operate as the device has got user-friendly design. Having equipped with precision components and units, this device ensures optimum performance and longevity. It does not degrade in quality or become inferior due to heat, voltage fluctuations, and other unfavorable conditions. Our customers can approach us to purchase the device from us at a reasonable price.

Efficient and Reliable Code Verification

The UNIPCR-10 delivers swift and dependable pharmaceutical code reading, supporting industry standards for interleaved 2/5 codes. Its high-speed optical sensor and accurate controller join forces to ensure every read meets stringent verification requirements, guaranteeing quality compliance for packaging lines. With an easy-to-use LCD display and semi-automatic operation, it minimizes manual errors while safeguarding product authenticity.

Versatile Design for Diverse Setups

This code reader offers flexible installation options, adapting seamlessly to various pharmaceutical settings. Compact and portable, the UNIPCR-10 can be wall-mounted or placed on a tabletop. Its durable mild steel construction with powder coating ensures longevity and resilience. Whether you are a manufacturer, supplier, or exporter, its practicality suits high-demand environments.

FAQ's of UNIPCR-10 Pharma Code Reader:

Q: How does the UNIPCR-10 Pharma Code Reader verify pharma codes on packaging lines?

A: The UNIPCR-10 uses an advanced optical sensor to scan interleaved 2/5 pharma codes on packaging. It processes scanned data through its integrated controller and displays the verification result on an LCD digital screen, ensuring codes are readable and comply with quality standards.Q: What are the main benefits of using this code reader over manual checking?

A: The UNIPCR-10 offers high accuracy (99.9%), faster processing (less than 1 second per read), and reduces human error. This makes code verification more reliable and efficient compared to manual inspection, supporting regulatory compliance in pharmaceutical operations.Q: Where can the UNIPCR-10 device be installed within a facility?

A: This model is versatile and can be mounted on a table or wall, making it suitable for various locations on a packaging line or quality control area within pharmaceutical manufacturing facilities.Q: When is it appropriate to use the UNIPCR-10 during the packaging process?

A: The UNIPCR-10 should be used during or immediately after the packaging step to verify that all printed pharma codes are accurate and meet industry standards before products progress further along the supply chain.Q: What is the standard process for using the code reader?

A: Operators position the packaging in front of the reader's optical sensor, allowing the device to instantly scan and verify the pharma code. Verification is completed within a second, and results are displayed on the LCD. The process can be repeated up to 10 times per minute.Q: Is the UNIPCR-10 compatible with different power supplies and environmental conditions?

A: Yes, the device is powered by a standard 230 V AC power supply and works efficiently in environments with temperatures ranging from 10C to 40C, fitting most pharmaceutical facility requirements.Q: What types of pharma codes can the UNIPCR-10 read and verify?

A: This model can read and verify all standard interleaved 2/5 pharma bar codes, commonly used on pharmaceutical packaging, ensuring compatibility with a wide array of products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese